Artificial Intelligence Takes NASA’s Hardware Design to New Heights

NASA's hardware design process is being revolutionized with the use of artificial intelligence, leading to lighter and stronger components.

NASA is turning to artificial intelligence (AI) to revolutionize its hardware design process, resulting in the creation of lighter and stronger alternatives. The space agency has been working with research engineer Ryan McClelland at NASA’s Goddard Space Flight Center, who has pioneered the design of spacecraft and mission hardware using commercially available AI software.

Summary

- Research engineer Ryan McClelland has pioneered the design of one-off spacecraft and mission hardware using commercially available AI software at NASA’s Goddard Space Flight Center

- The hardware, dubbed “evolved structures,” is designed by starting with the mission’s requirements and defining the surfaces where the part connects to the instrument or spacecraft

- The AI produces complex structure designs in as little as an hour or two, but still requires human oversight to ensure the structures look right

- The evolved structures save up to two-thirds of the weight compared to traditional components and can be milled by commercial vendors in as little as one week

- The parts are analyzed using NASA-standard validation software and processes to identify potential points of failure

- The parts generated by the algorithm have been found to lower risk after stress analyses

We don’t run ads or share your data. If you value independent content and real privacy, support us by sharing.

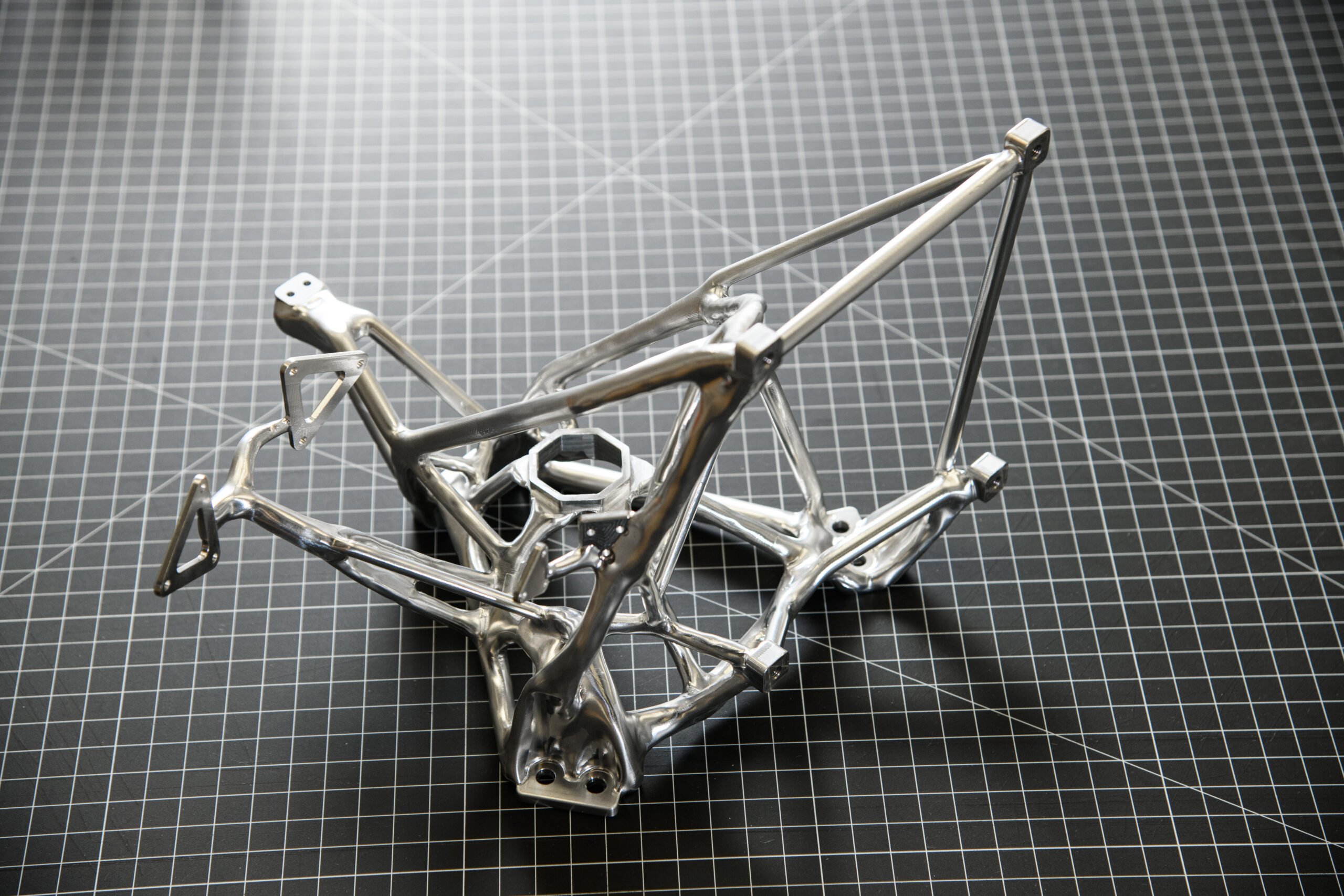

The resulting hardware, dubbed “evolved structures,” is produced by the AI software, which begins the design process by analysing the mission’s requirements and defining the surfaces where the part connects to the instrument or spacecraft. The AI then produces complex structure designs in as little as an hour or two. Although the AI requires human oversight to ensure the structures look right, the evolved structures save up to two-thirds of the weight compared to traditional components and can be milled by commercial vendors in as little as one week.

Spacecraft and mission hardware designed by an artificial intelligence may resemble bones left by some alien species, but they weigh less, tolerate higher structural loads, and require a fraction of the time parts designed by humans take to develop,” says an unnamed speaker. McClelland adds, “They look somewhat alien and weird, but once you see them in function, it really makes sense.”

The AI-generated parts are analysed using NASA-standard validation software and processes to identify potential points of failure, and the use of AI has lowered the risk of failure. “After these stress analyses, we find the parts generated by the algorithm don’t have the same issues as parts designed by humans,” says McClelland.

The use of AI has also sped up the design process, with the ability to perform the design, analysis, and fabrication of a prototype part in as little as one week. “It can be radically fast compared with how we’re used to working,” says McClelland.

Balancing Human and AI Input

However, while AI has revolutionized the design process, human input is still necessary. McClelland notes that “the algorithms do need a human eye. Human intuition knows what looks right, but left to itself, the algorithm can sometimes make structures too thin.”

In conclusion, NASA’s adoption of AI technology has revolutionized its hardware design process, leading to the creation of lighter and stronger alternatives. The evolved structures produced by the AI are analysed using NASA-standard validation software and processes to ensure their effectiveness, and human oversight is still necessary to ensure the structures look right.